The process involves the refining of metals and alloys and the removal of dissolved and chemical bonded impurities resulting in an end product that is clean and homogeneous.

Vacuum induction melting furnace pdf.

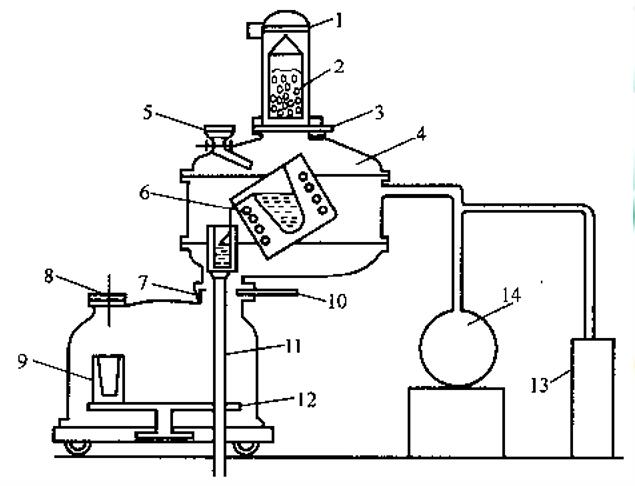

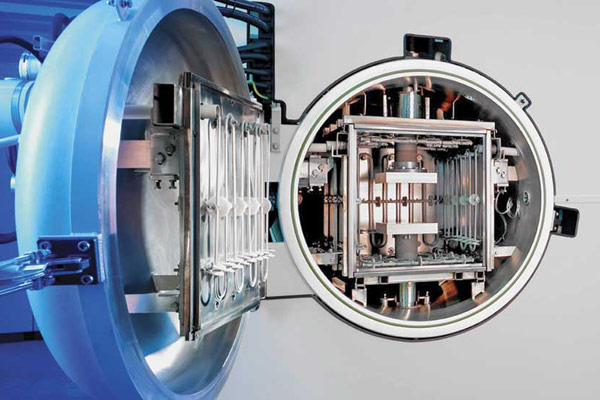

1 basic elements of a vacuum induction melting furnace heating coil cooling coil ground detection brick crucible shunt fig.

Power window ladle systems.

Each vacuum induction furnace has a rated batch capacity of 2 000 kg.

A gas recycling system recovers the inert gas for reuse.

Vacuum induction melting systems.

Induction coil to vacuum pumps fig.

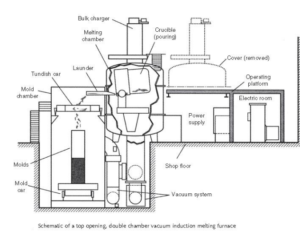

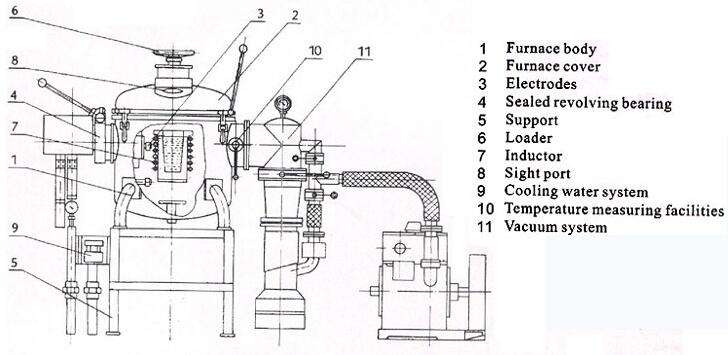

The vacuum induction process uses a completely enclosed airtight vessel under vacuum.

Casting volume 15 handbook committee p 1 8 doi.

2 schematic of vacuum induction melting crucible shell coil stack backup lining and working lining asm handbook volume 15.

Induction systems for vacuum and controlled atmospheres.

1st tilt the furnace to 30 to 400c and the power supply.

In induction melting furnaces should be charged carefully to avoid bridging of the charge excessive temperature in the bath below the bridge can cause rapid erosion of the furnace lining and a dangerous run through which could cause an explosion.

Vacuum induction melting vim is the melting of metal via electromagnetic induction under vacuum.

Present practices followed in induction furnaces are discussed in this paper.

Ladle refining furnaces lrf.

Drying and preheating systems.

The vacuum induction melting vim process involves the melting of metals by electromagnetic induction while under vacuum.

Steel billet making systems.

High resistance load hrl melting systems.

The furnace consists of a refractory vessel or crucible surrounded by a water cooled copper induction coil.

Indispensable for high purity metals current processing route for products cast from vim furnaces beside the primary vim melting of the so called master.

Conventional air melting techniques.

An induction furnace containing a refractory lined crucible surrounded by an induction coil is located inside a vacuum chamber.

A mechanical vacuum pump system is the most common method of evacuating the air from the chamber.

3 vacuum induction melting enables a precise adjustment of the alloy composition and melt homogenization of the master alloy.

A new generation of industrial induction melting furnaces has been developed during the last 25 years.

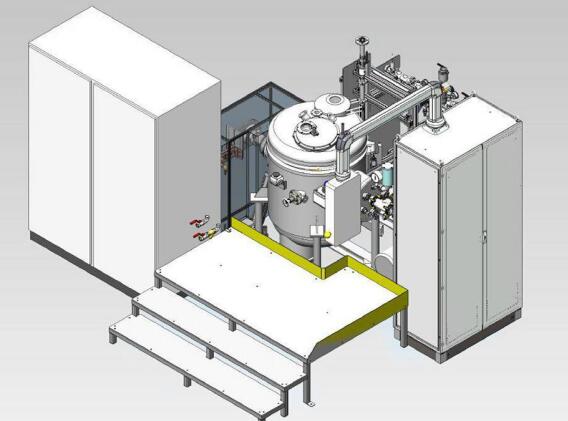

Schematic design of a large scale atomization unit with a double door melting furnace chamber powder collection system of a large scale atomization unit the tundish cart can be moved sideways to a.