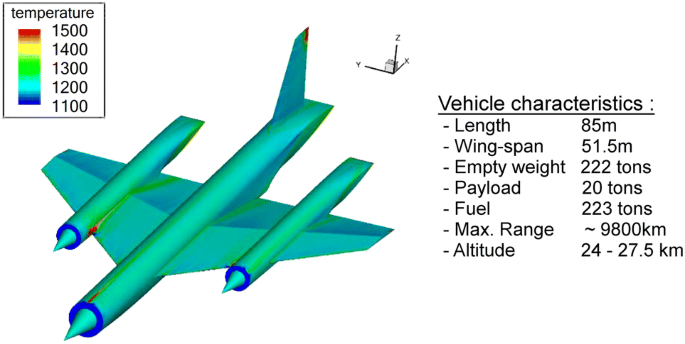

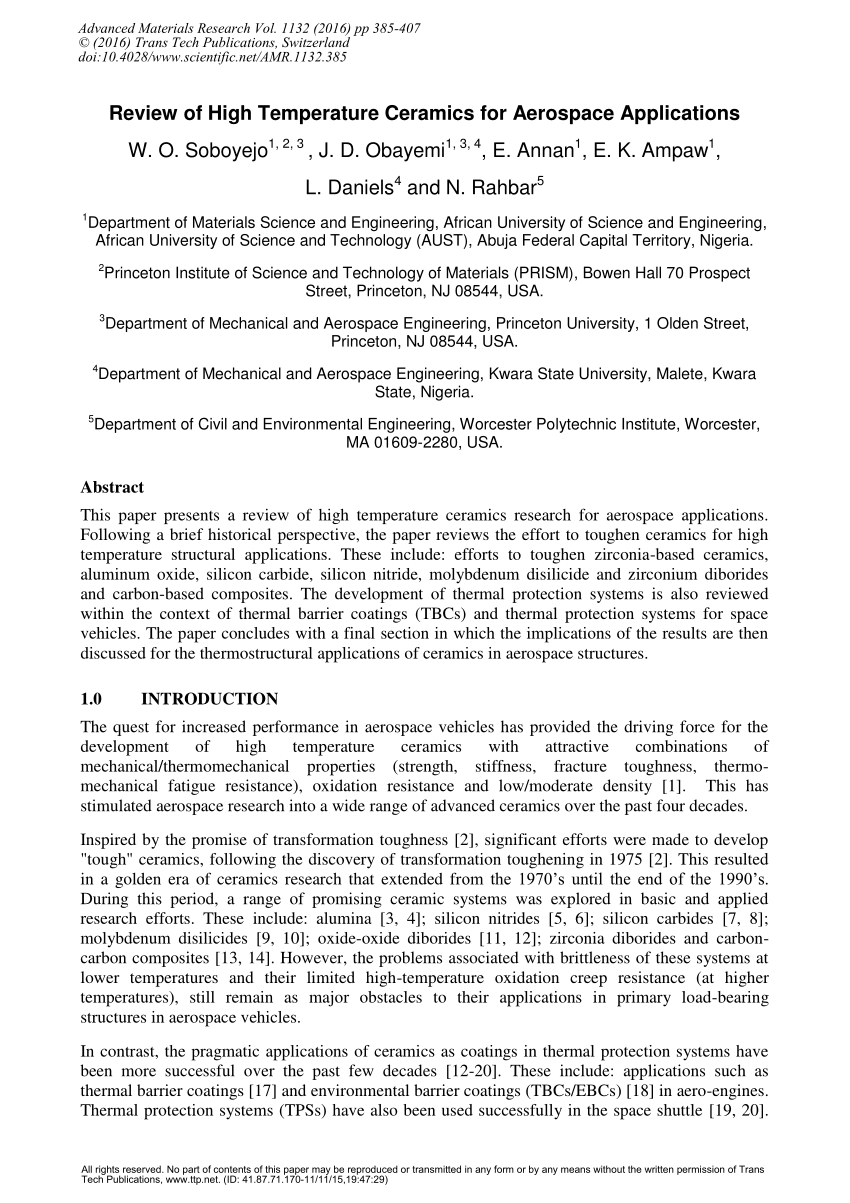

In aerospace applications ceramics are primarily found in engine and exhaust systems thermal protection shields and structures for ultra high speed flying objects.

Ultra high temperature ceramics for aerospace applications.

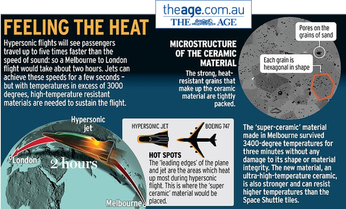

Temperatures above 1600 c and possibly exceeding 2200 c will be described as an ultra high temperature region to differentiate unique thermo mechanical and thermo chemical demands of aerospace applications.

Current efforts have focused on heavy early transition metal borides such as hafnium diboride and.

Indeed hypersonic flights re entry vehicles propul sion.

Ultra high temperature ceramics are a class of refractory ceramics that offer excellent stability at temperatures exceeding 2000 c being investigated as possible thermal protection system materials coatings for materials subjected to high temperatures and bulk materials for heating elements.

Ultra high temperature ceramics for aerospace applications the open aerospace engineering journal 2010 3.

Ceramics and ceramic matrix composites that can withstand temperatures as high as 1 600 c are used to manufacture lightweight turbine components that require less cooling air such as vanes blades nozzles and combustion liners and parts for the exhaust system that enhance acoustic attenuation and have a long life thanks to.

Broadly speaking uhtcs are borides carbides nitrides and oxides of early transition metals.

.jpg)

.jpg)