Fluid power seals sizes readily available in a multitude of materials to provide optimal compatibility with the various hydraulic fluids encountered in service.

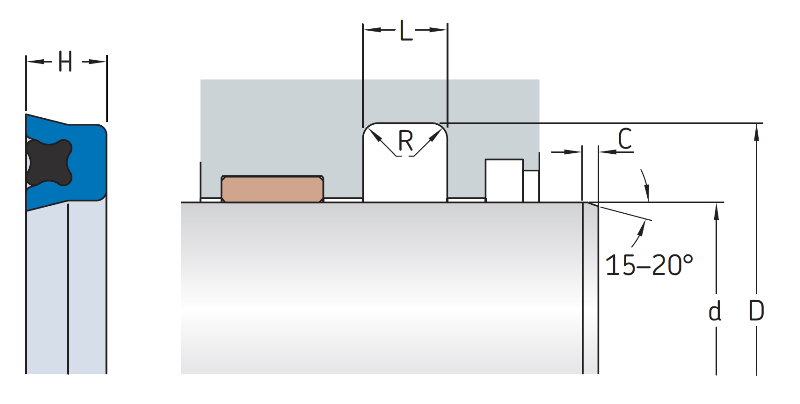

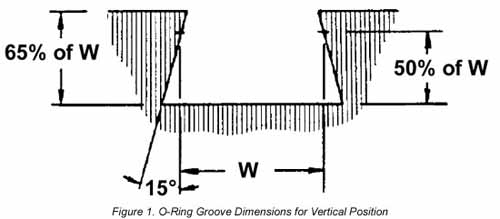

U cup seal groove design.

Hydraulic sealing solutions for fluid power applications have become a priority in our continued product offering.

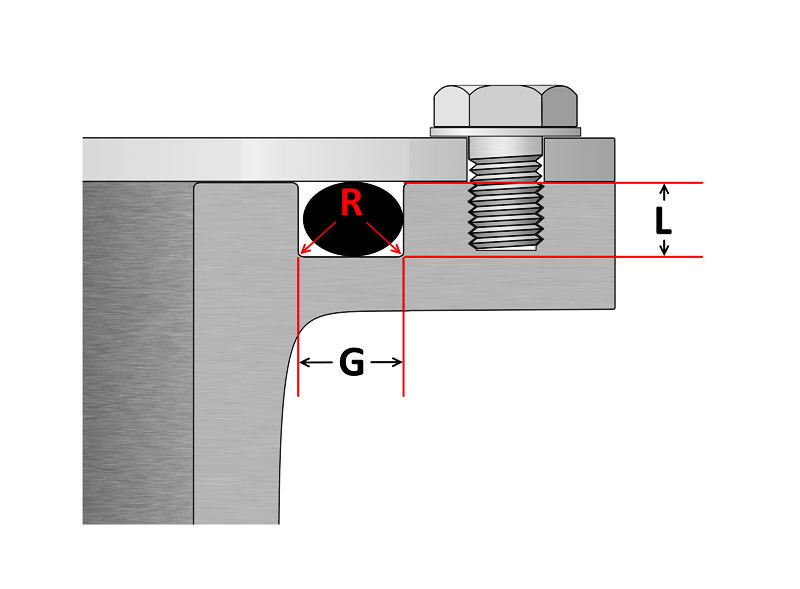

Interference fit in the groove.

The seal design and the polyurethane properties give efficient fluid sealing reduced friction values and low wear rate.

Also known as type b seals loaded lip seals and polypaks these u cups are wider than our other o ring loaded u cup seals for better stability and fit in wider grooves.

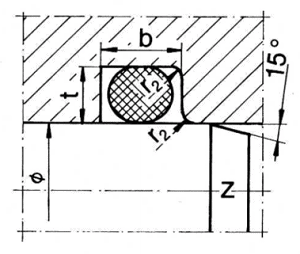

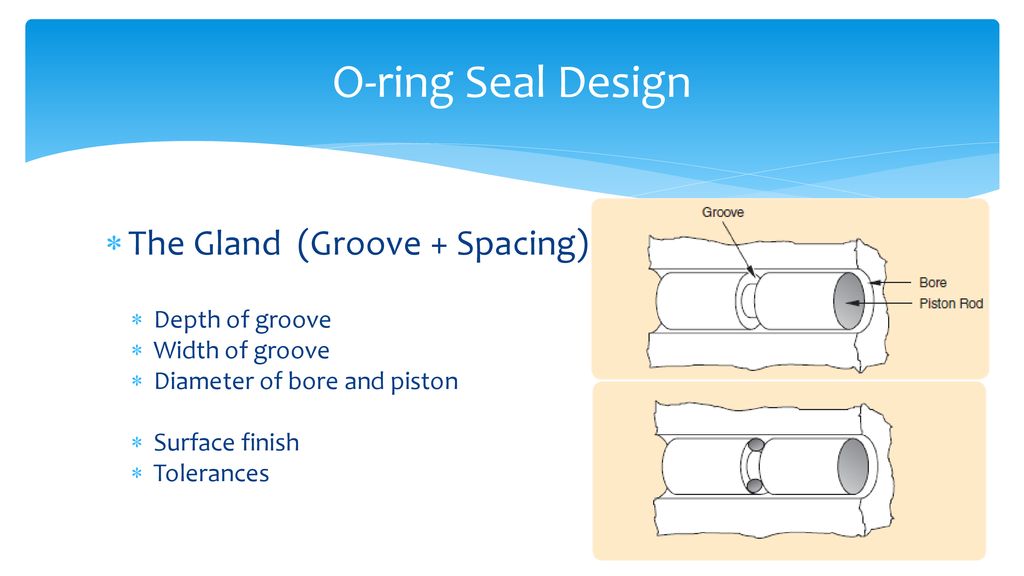

Groove depth refers to the axial dimension of the seal gland and adequate space is required for the o ring loaded u cup to perform properly.

Parker s 8400 profile u cup is a light load symmetrical lip seal for use in either rod or piston sealing applications.

U cup is a specialized piston seal design.

Squeeze in this area would result in an extremely high loading of the sealing lips and can result in increased friction heat seal wear and likely premature seal failure.

Lip seal with straight cut scraper lip design 6 10 bpp o ring energized u cup per lip seal with beveled lip design 6 14 sl dual compound dual lip seal 6 24 us symmetrical u cup seal 6 27 series description light load u cup with 6 18 8500 light load u cup with scraper lips 6 18 an6226 symmetrical army navy an specification 6 30 catalog eps.

The design is suited for situations where space is limited.

P figure 8 u cup.

These seals are suitable for closed groove installation.

The seal is most commonly used in pneumatic applications as a rod or piston seal.

Homogenous u cups block vees are a non loaded single material u cup.

Developed from the standard symmetrical u cup.

An o ring secures them to the rod or piston preventing leaks at low pressure and as the seal wears.

The thin flexible lip design reacts to low pressure and provides an extremely smooth steady movement with less break away force required because of the inherent low friction.

U cup has an id smaller than the groove for which it is intended.

Heel of the u cup.

It assures improved sealing performance due to the following features.

These u cup seals create less friction than o ring loaded u cups so they wear more slowly also known as lip seals u cups have a sealing lip on both the inside and outside edges so they can be used for rod and piston sealing.